| |

- Articles View Hits

- 4349538

We have 226 guests and no members online

PROJECT MUSLIN

Background of Project Muslin :

Under British rule, the British East India company could not compete with local muslin with their own export of cloth to the Indian subcontinent.

Though Gandhiji believed Khadi can play a vital role in the economic growth of the nation the Bengali muslin industry was suppressed by various colonial policies. As a result, the quality of muslin suffered and the finesse of the cloth was lost.

There have been a few attempts at reviving the muslin industry even after independence. In the present day, many different types of muslins are produced in many different places.

It surfaced that those who were attached with Muslin compelled to shift to the other profession as they could not get benefits they were entitled to. Due to lack of storage and lack of proper marketing and it has become a seasonal occupation. They were in despair, the hands that could weave dreams, that could create beauty were becoming listeners. The Youth were either not learning or unlearning the teaching of their forefather. Some of them became agricultural workers, some of them started pulling rickshaw. The West Bengal Khadi & Village Industries Board has rightly seized of the opportunity and has given utmost importance to intervene in the following areas.

1. Skilling/Training : It is an important Policy Priority for Bengal Muslin.

2. Infrastructural Support.

3. Quality Control.

A revival package for superfine cotton-thread has been taken up under ‘PROJECT MUSLIN’ by the Department of Micro, Small and Medium Enterprises and Textiles, Government of West Bengal. Its primary objective is to revive the muslin industry and ensure that the artisans get remunerative returns and appreciation for their unique skills. WBKVIB was entrusted to implement the project.

It was indeed an honour for the WBKVIB made a MOU with Kolkata Craft Combine Society for soft intervention to the Muslin artisans.

1. Skilling/Training :

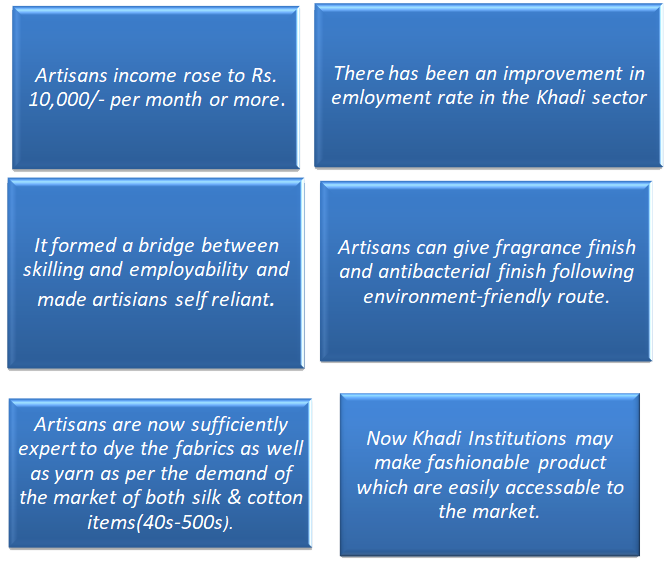

WBKVIB’s policy intervention have translated into concrete programmes of action which addressed four major skill challenges – scale, quality, employability and aspirations and several interventions have been introduced in both short term and long term.

Upskilling and reskilling a key component of the skill ecosystem.

WBKVIB had been imparting skill training across the state through Privet Partners.

Skilling is destined to become a great success in coming years and widen the opertunities for women in big way added to this is the need to diversify Products of Khadi Muslin.

Start ups showed that there were huge prospects ahead and little more encouragement and support from the KVIB would bring out the desired result.

Training Projects were allocated to those trainers who can train properly so that weavers can change themselves with the changing time. This is a perfect case study as to how all concerns can join hands.

Skilling had been receiving focused attention. Skilling helps to familiarize the artisan with latest technology and design and help to upgrade the product to the Global standard with better dyeing process and weaving techniques.

The artisans were mostly poor exposure to new technologies. Series of efforts had been taken to redress this problems and the sector is now witnessing good growth in terms of product developments.

| Sl No.

|

NAME OF THE DISTRICT

| TRAINING ON | |||

|---|---|---|---|---|---|

| SPINNING | WEAVING & DESIGNING | DYING & PRINTING | PRE LOOM | ||

| 1 | MURSHIDABAD | 19 | 04 | 02 | 01 |

| 2 | MALDA | 12 | 0 | 0 | 0 |

| 3 | BURDWAN | 08 | 01 | 01 | 0 |

| 4 | BIRBHUM | 12 | 03 | 01 | 01 |

| 5 | NADIA | 08 | 02 | 02 | 0 |

| 6 | PASCHIM MEDINIPUR | 01 | 01 | 01 | 0 |

| 7 | BANKURA | 04 | 02 | 01 | 0 |

| 8 | HOWRAH | 04 | 04 | 0 | 02 |

| 9 | HOOGLY | 06 | 01 | 0 | 01 |

| 10 | 24TH PGS (N) | 01 | 0 | 0 | 0 |

| TOTAL | 75 | 18 | 08 | 05 | |

Training of high count Muslin (400s – 600s and above)

Matiary Kutir Shilpa Pratisthan at Nawadwip is the facilitating agency which runs the training center under WBKVIB for creating Muslin fabric of 500 count and plans to take up the challenge of producing fabric as fine as 600 counts. There are approximately 60 women that work in the

unit and they plan to extend it to more women of the area and make it a complete unit handled exclusively by women.

|  |

Training of Muslin(High count) at Matiary Kutir Shilpa Pratisthan,Nabadwip,Nadia

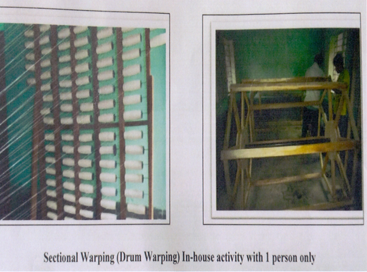

MODERNIZATION OF PRE-LOOM/WEAVING PREPARATORY SECTION FOR KHADI SECTOR

West Bengal Khadi & Village Industries Board had taken a project of “Pre-Loom/Weaving Preparatory Section” in the arena of Khadi Sector in association with Govt. College of Engineering & Textile Technology, Serampore.

1. Preparatory process is the backbone of weaving performance i.e. quality and production. In Khadi, the primitive process is laborious and time consuming. As a result the suitable process is to be developed for preparatory section of Khadi Industry is utmost essential.

2. The aim of this project is to enhance the quality of Khadi fabric and also to resolve the problem associated with Khadi Weavers and Khadi Weaver’s family by adoption of appropriate technology with the modification and mechanisation of Yarn preparation process which will reduce the work load and time of Weavers and thereby to resolve the social problem associated with the Khadi Weavers and Khadi Weaver’s family.

3. Hence, the aim of this project is to improve the Khadi preparatory process by (i) Method of wetting of yarn prior to sizing (ii) Modification of sizing paste preparation (iii) Elimination of step by modification of sizing recipe (iv) Improvement of knotting technique (v) Introducing of sectional warping over peg warping and (vi) Mechanised winding process.

AT A GLANCE (Outcome of the Project)

| Sl. No. | Section | Previous | Now | Outcome |

| 1. | Yarn Wetting Process | Process time:4-5 days | Process time: less than 1 days | Loom waiting time reduces by minimum of 3 days |

| 2. | Sizing Paste Preparation | Rice Dust Paste | Latai making is Eliminated | New recipe for enhances the quality and productivity |

| 3. | Latai Making Process after Sizing | 1. Making of Latai (Cage Winding) from wet sized yarn 2.Drying of yarn in overlapped condition drying is time consuming | 1.Yarns are dried in more open form 2.Drying time is reduced 3.Drying can be done in house. | Elimination of tedious process reduces the loom waiting time |

|

Making of লাটাই from wet sized yarn causes entanglement. |

Use of rice based starch for sizing causes damage to yarn on storage |

|

Infrastructural Support

I. An infrastructure – Comprising Physical Infra, technology and innovation support. WBKVIB is on spree of revival of the glory MUSLIN KHADI, at the grass root level and in the past years 4633 nos. appropriate CHARKHAS and 4580 nos. advanced looms were supplied to the selected Muslin artisans who possess enough potential and possibilities. These units can be on the way to becoming the piller of growth. Availibilities of infrastructure means access to latest technology.

| SL NO. | District | No. of Charkha | No. of loom supplied |

| 1. | Paschim Medinipur | 15 | 250 |

| 2. | Purulia | 52 | 86 |

| 3. | Nadia | 283 | 64 |

| 4. | Murshidabad | 1606 | 1282 |

| 5. | Malda | 1228 | 785 |

| 6. | Howrah | 244 | 168 |

| 7. | Purba Medinipur | 30 | 10 |

| 8. | Hooghly | 110 | 24 |

| 9. | Burdwan | 339 | 124 |

| 10. | Birbhum | 378 | 729 |

| 11. | Bankura | 70 | 769 |

| 12. | Darjeeling | 1 | 240 |

| 13. | 24 Parganas (N) | 183 | 38 |

| 14. | 24 Parganas (S) | 77 | 0 |

| 15. | Head Quarter | 2 | 0 |

| 16. | KCCS (Facilitator) | 15 | 11 |

| TOTAL | 4633 | 4580 | |

II.The possibilities and potential for job creation and weath formation are immence in the Khadi Sector and to provide gainful employment at the doorsteps of the rural un-employed, especially youth and women. Women’s emancipation and empowerment at the core of all development activities of WBKVIB. Within good infrastructural facilities the building of CPC is an important and so far 496 nos. CPC have been completed and 96 nos. will be completed soon for the place of working Muslin Artisans.

STATEMENT FOR WORKSHED SCHEME

| SL NO | District | No of Proposal Received | No. of Proposal approved | No of Proposal Accepted | No. of Proposal under process | No. of Proposal rejected | No. of artisan deposited own contribution | Fund disbursed for no. of cases | Fund to be disbursed for no. of cases | Fund disbursed (Rs.) |

| 1. | HOOGHLY | 3 | 0 | 1 | 0 | 2 | 0 | 0 | 0 | 0 |

| 2. | NADIA | 3 | 0 | 0 | 3 | 0 | 0 | 0 | 0 | 0 |

| 3. | BIRBHUM | 256 | 172 | 0 | 0 | 84 | 167 | 86 | 81 | 9674265/- |

| 4. | MURSHIDABAD | 279 | 278 | 1 | 0 | 0 | 278 | 278 | 0 | 31272645/- |

| 5. | BANKURA | 24 | 23 | 0 | 0 | 1 | 12 | 12 | 11 | 1349897/- |

| 6. | PURULIA | 53 | 41 | 0 | 0 | 12 | 39 | 38 | 1 | 4274675/- |

| 7. | HOWRAH | 13 | 13 | 0 | 0 | 0 | 13 | 13 | 0 | 1462396/- |

| 8. | PURBA BURDWAN | 28 | 26 | 0 | 0 | 2 | 19 | 19 | 3 | 2087482/- |

| TOTAL | 659 | 553 | 2 | 3 | 101 | 528 | 446 | 96 | 50121360/- | |

It is an attempt to facilitate the development of Khadi spinners and weavers essentially belonging to BPL category by providing them financial assistance for construction of worksheds, on pilot basis.

Financial Assistance for construction of workshed will be provided to those Khadi Artisans who belong to BPL category through the Khadi institutions with which these khadi artisans are associated.

Quality Control :

Quality Control is a set of steps or guidelines designed to guarantee that a product (Khadi Fabric) meets certain performance standards and customer expectation. The above is generally measured by various production components or a set of steps or guidelines

|  |

The entire components and tested at Board’s in house testing laborotary by the experienced textile engineers before receiving any such fabrics which is in brief :

- Yarn testing : yarn occupies the intermediate position in the manufacture of fabric from raw materials. Yarn results are therefore essential, both for estimating the quality of raw material and controlling the quality of fabric produced.

- Sampling : the sampling must be true and representative of the Bulk lot.

- Ambient condition for yarn testing : Elongation, yarn evenness, imperfections, count etc. temperature 20+ 2 degree centigrade.

|

Raw materials of Muslin Khadi Fabric | A Khadi Institution (may be either the fold of KVIB or KVIC) Producing Muslin Khadi can only develop higher performance and sustainable profit ability if the quality standard are maintained (in sync) to the global standard. It also enhance competitiveness in Muslin Khadi Industry. The programme aims to develop global competitiveness among Bengal’s Muslin Khadi Producers by improving the process design techn ology and market access. It also aims at value – added cost effective solution. Muslin Khadi is already repositioning on the Khadi Map. |

Board has set up a physical testing of cotton yarn and fabrics, chemical testing of cotton fabrics testing laboratory and also for the standardization of the parameters which is an ultramodern lab manned by qualified personal to ensure maintenance of quality to meet the stringent standard. We may test both physical and chemical properties of the yarn and fabric. (ISO certificate obtained and furnished below).