KHADI MARK

QUALITY CONTROL

Quality is an important dimension of Production. KVIB control the quality of Cotton Khadi, Silk Khadi Product through –

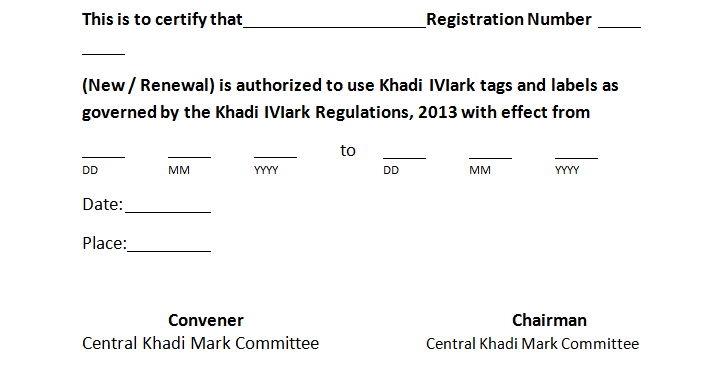

A. Khadi Mark certificate issued by the KVIC as the genuineness of Khadi

B. Quality Control Management of Product, by the WBKVIB’s officials.

A. Khadi Mark : - It has become mandatory for all the Khadi Producing Institutions to get registered for “KHADI MARK” certificate for genuineness of Khadi. The Khadi Institutions who have obtained the “KHADI MARK” Certification shall only be considered for enlistment under Govt. supply

THE PROCEDURE OF OBTAINING “KHADI MARK”

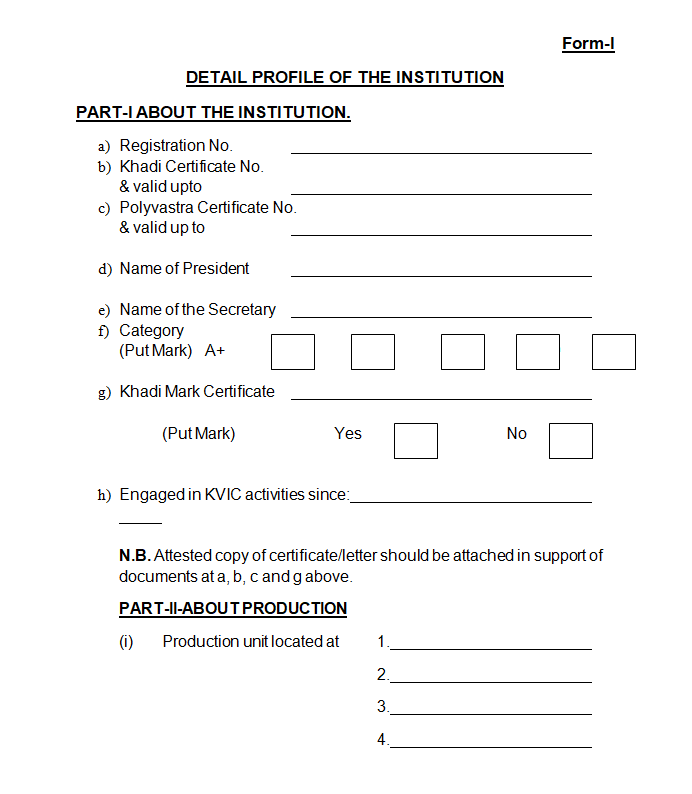

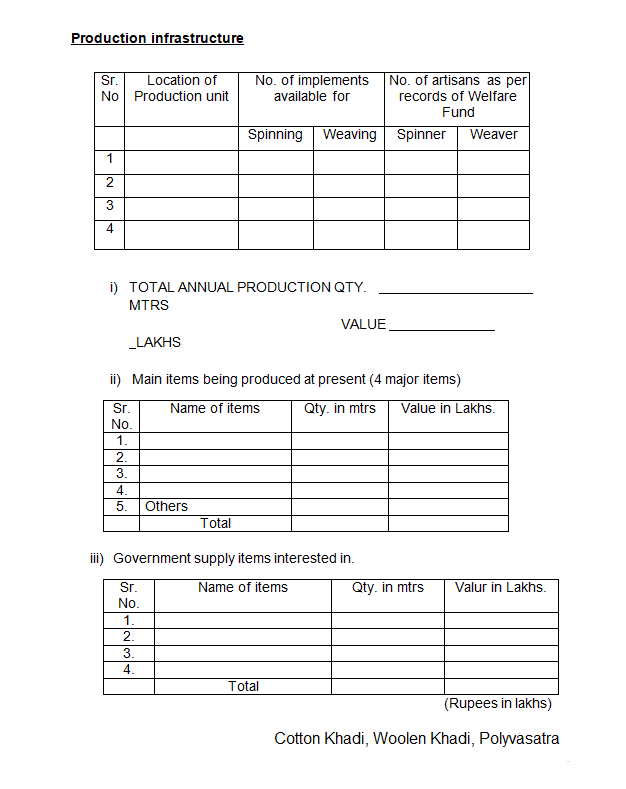

The intending Khadi institutions registered with KVIB/KVIC having adequate infrastructure facility desirous to enlist themselves under Govt. Supply in respect of their product will apply to respective State/Divisional office as per the prescribed format alongwith the requisite forms for enlistment.

FORM FOR REGISTRATION OF NEW INSTITUTION FOR SUPPLY OF MATERIAL FOR RC-ITEMS AND

NON-RC ITEMS

1. Name & Address of the Institution : -

2. a) Registration No.

b) Khadi Certificate/Mark No. :-

Validity up to : -

(Attested copy enclosed)

3. Whether Directly Aided/Board Aided : -

4. Date since when Khadi Program is

being implemented : -

5. Total Production capacity itemwise : -

6. Items interested in supplying : -

7. Quantity (item wise) which can be supplied per month : -

8. We undertake to supply material strictly

as per required specification & as per

Khadi certification norms, failing which

we shall be solely responsible and liable

for any penalty/charges etc. levied by

KVIC/DGS&D etc. : -

Signature of Secretary/

Authorized representative of the Institutions

Checklist for enlistment enclosed base on various details in checklist and physical verification report, the institutions is recommended for enlistment.

(State/Divisional Director)Khadi and V.I. Commission.

iv) Production Targets:-

Previous year:-

Current year:-

v) Performance:-

Previous year:-

Current year (Till date):

vi) Raw-material procured:

Previous year:

Current year (Till date):

vii) Raw material procured from C.S.P:-

Previous year:-

Current year (Till date):-

viii) Raw material procured from open market:-

Previous year:-

Current year (Till date):-

Signature of the Secretary along with seal of the Institution

The Khadi institutions enlisted under Directorate of Marketing/Govt. Supply for undertaking of Rc and Non-Rc items need to pay a non-refundable amount of Rs. 5000/- per annum per product every year to the Directorate of Marketing/Govt. Supply. It is mandatory on the part of Institutions, who have already and propose to be enlisted, should remit the registration charge every year by paying Rs. 5000.

B. Quality Control Management :- Besides Khadi Mark KVIB also ensures about the quality of the Khadi Product. Quality Implementation is a “Total organization effect”.

Quality is the performance of the product as per the commitment made by the Khadi producer to the consumer. The commitment may be explicit such as written contract or it may be implicit in terms of the expectation of the average consumer of the product.

Once strategic decision regarding the quality is taken, it is the job of all functional Officers, including the production and operations manager, to see that such strategic objectives and goals are implemented.

There are three aspects of assuring quality.

• Assurance of incoming raw materials quality.

• Assurance that proper processes are operating on the raw materials.

• Assurance of the quality of the outgoing furnished goods.

The task of exercising control over the incoming raw materials and the outgoing finished goods is usually called ‘Acceptance Sampling’. Here, one is concerned about accepting or rejecting the supplier’s raw materials, and sending or not sending the finished goods out. This is why the control of the raw material and the finished goods point is called Acceptance Sampling. This is one part of what is known as ‘Statistical Quality Control’

A single sampling plan in which accept/reject decisions are based on the result of a single sample of item from the lot items through Board’s in house testing labrotory. Each of the sample items is inspected and categorized as either acceptable or defective. Such a plan is known as Sampling by Attributes what KVIB is following.